Break-Off is a standard arrowhead equipped with one or more break-offs at its end. This break-off system gives high flexibility for arrow tuning.

Shape: Bullet - Shape: Tungsten (Wolfram):

This classic form is used very often in Fita target shooting. Through its round shape it is a little gentler to the target and easier to drag out.

Material:

Tungsten is a brilliant white metal with high hardship, density and consistency. It is about three times as heavy as conventional stainless steel and is used for arrowheads to shift the weight even more into the arrow point. This gives the arrow tuning another advantage.

The deposit of tungsten on the surface of the earth is about 0,0001 g/t. Therefore tungsten is a very rare metal and accordingly very expensive.

Break-Off Technology:

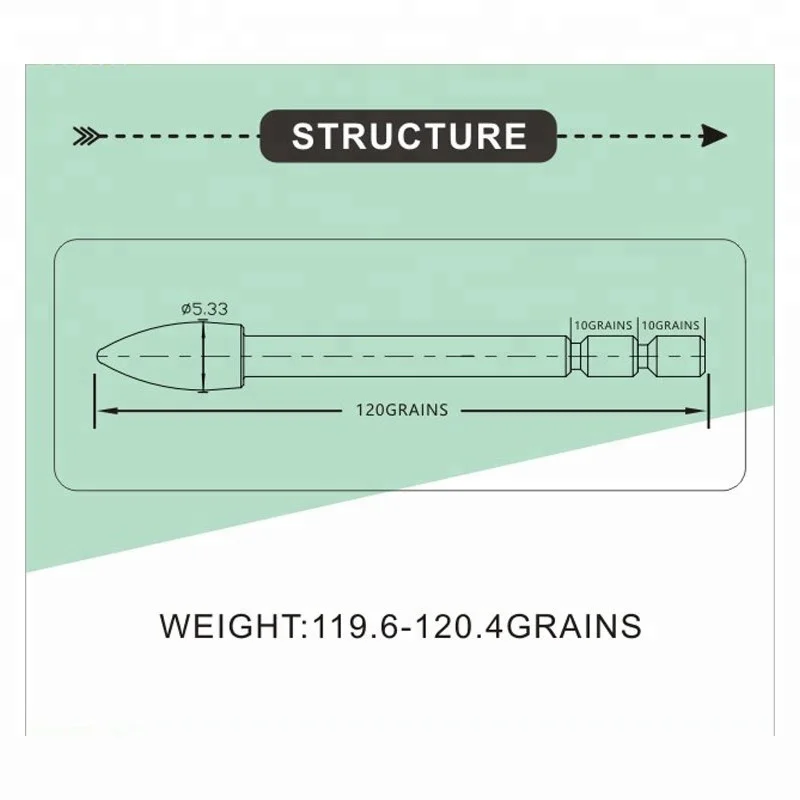

Break-Off points conform the standard arrowheads for carbon arrows with the feature that it is possible to tune the weight.

The grooves for the glue, at the shaft of the head, are purposely low- shaped. This prevents the usage of too much glue. Wrong spread glue can cause imbalance.

Installation: After about 60 seconds the Break-Off point sticks perfectly together with the carbon shaft .Beforehand the carbon shaft has to be whet from the inside and cleaned with a solvent. 1-2 drops of Bond onto the shaft of the head and push in a rotating movement all the way until it is tight fastened.

Run- point accuracy of the arrow point: 0.006 µ

Break-Off:

The head has one or more break-offs at its end. These break-offs can be broken off at leisure to get the ideal arrowhead weight.

Special insertions at the break off area make sure that the tolerance of the weight, after breaking- off a part, is absolutely slight.

Tungsten points seems to have three advantages compared to normal points for X10's:

1. They are shorter (by about a centimeter): and hence result in the arrow having a lower side area.

2. They are heavier (by 10 grains): and hence result in a heavier arrow.

3. They seem less likely to bend (certainly compared to the standard points). The stainless steel points will bend simply because they are long compared to the tungsten points, but will bend less than the standard points. This also means that where with standard points you may need to replace them from time-to-time, tungsten points may last for several sets of arrows.

Point 3 is important from the point-of-view of longevity of your arrows. If a point bends it is quite likely that the carbon near the front will be damaged, and you may lose an arrow.

Points 1 and 2 utlimately mean that with tungsten points the arrow will drift less. By the calculation the drift is reduced by about 3% through the combination of less surface area and higher weight. Not a lot, but every bit counts.

TEL:

TEL:

TEL:

TEL: