Product introduction

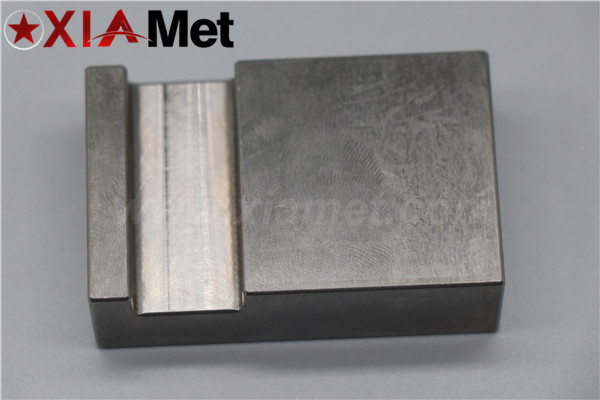

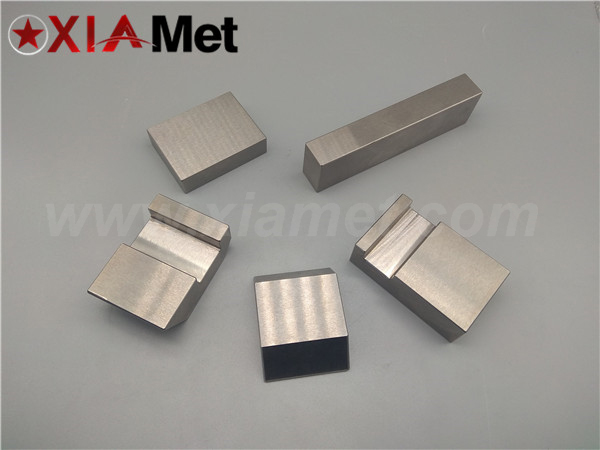

Item name:Tungsten bucking barMaterial:W-Ni-Fe, W-Ni-Cu

Standard:ASTM-T-21014/ASTM B 777-07

Packaging:Plywood wood case

Application:buck tails on rivet guns

Brand name:XIAMET

Place Of origin:China

Inquiry us:sales@sxxinheng.com

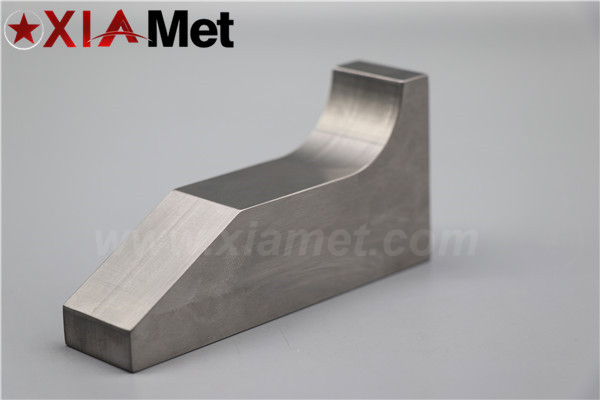

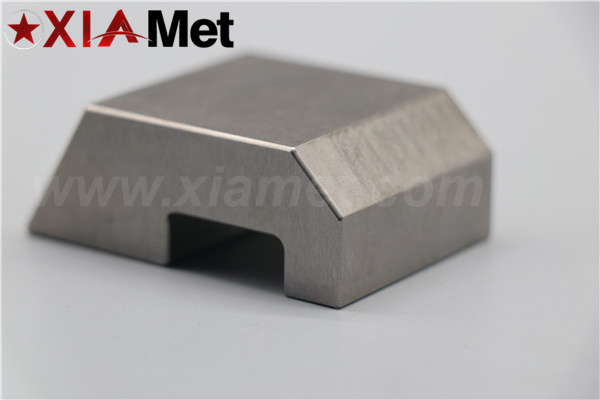

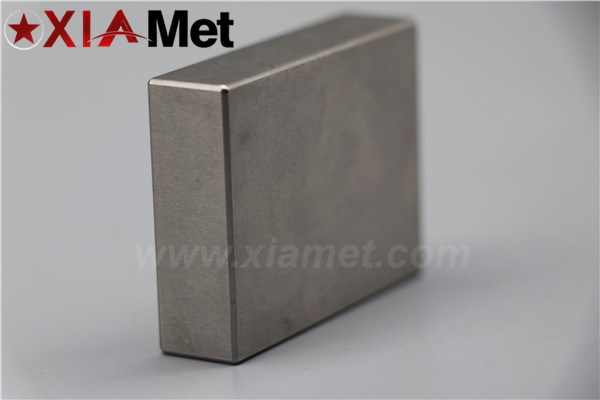

Tungsten bucking bar

Tungsten alloy bucking bars are placed behind work surfaces to provide a backing member in applying impact fasteners and including intermitted tool head and handle parts with a low-recoil impact-absorbing spacer provided there between to take shock loads in compression and shear. A rivet gun is a type of tool used to drive rivets; nearly all rivet guns are pneumatically powered.

Bucking bars are used on the backside of a metal rivet gun to counter the force of the hammering and to create bucktail. Bucking bar also can be used to absorb the force of rivet guns, reducing the vibration of bucking.

Tungsten alloy bucking bar used to form buck tails on rivet guns. And bucking bars come in many different shapes and sizes, and they are normally made from alloy steel similar to tool steel. The particular shape to be used depends upon the location and accessibility of the rivet gun to be driven.

The size and weight of tungsten bucking bars depend on the size and alloy of the rivet gun to be driven. Under certain circumstances, and for specific rivet installations, specially designed bucking bars can be manufactured.

|

Specification |

||||

|

Material |

Density ( g/cm3 ) |

Tensile Strength ( Mpa) |

Elongation ( % ) |

HRC |

|

90W-Ni-Fe |

16.9-17 |

700-1000 |

20-33 |

24-32 |

|

93W-Ni-Fe |

17.5-17.6 |

100-1000 |

15-25 |

26-30 |

|

95W-Ni-Fe |

18-18.1 |

700-900 |

8-15 |

25-35 |

|

97W-Ni-Fe |

18.4-18.5 |

600-800 |

8-14 |

30-35 |